September 26 2013

Solar-electric catamaran Decision 56E

Development of the projet Decision 56E.

This boat is forseen to become the new "Caprice 3" operated by the Compagnie de Navigation on the lake of Joux.

Download the presentation flyer.

September 23 2013

Volvo Ocean 65 hits the water at start of new era

The Volvo Ocean Race offered a glimpse of the future on Monday when the first of the radical new Volvo Ocean 65 racing yachts being built for the next two editions left the Green Marine boatyard in the UK and hit the water for the first time.

Radical, high-performance, tough and purpose built to deliver the best multimedia material possible – the new Volvo Ocean 65s mark the first use of a one-design boat in the 40-year history of the Volvo Ocean Race.

The striking new 65-foot yacht was designed by Farr Yacht Design in the United States and built by a consortium of boatyards in the UK, France, Italy and Switzerland. The fleet of new boats will be used for the first time in the 12th edition of the round-the-world race starting in just over a year’s time on October 4 2014 in Alicante and will be tough enough to be used again in 2017-18.

"This is a stunning looking boat," said Patrick Shaughnessy, President of Farr Yacht Design. "It has an iconic look that really marks it out as special and the build quality is stunning."

Team SCA, the first team to enter for the 2014-15 edition and the first all-female campaign in over a decade, are taking delivery of the new boat, which will undergo rigorous testing this week before a series of sea trials and system checks.

After a build process involving a more than 120 people and 36,000 man-hours, SCA’s boat was taken on Monday by barge from Green Marine to a nearby boatyard in Southampton. The boat will undergo pull-down testing on Tuesday and could be sailed for the first time on Wednesday.

The boat has been designed with digital communications very much in mind and strategically placed cameras and microphones will ensure better footage than ever is sent back from the oceans by the Onboard Reporters.

“The amazing communications capabilities mean we can focus directly on the sailors and the enormous challenges they face out in the oceans,” said Volvo Ocean Race CEO Knut Frostad.

“It’s also a very efficient boat from the point of view of sponsors. The costs have been dramatically reduced along with the risks of serious breakages – all while keeping very high speed and performance.”

Source: Volvo Ocean Race

September 20 2013

Team Hydros Kicks-off Little America’s Cup Challenge at the C-Class World Championship

Hydros poised for competition with two revolutionary boats and outstanding crews.

Two crews competing for Team Hydros will be representing Switzerland during the C-Class World Championship – also called the Little America’s Cup – starting in Falmouth, England on Sunday, September 22.

The four sailors of Team Hydros as well as the technical team have been training for over a year for the C-Class World Championship, catamarans that “fly” above the water using wingsails at the forefront of technology. The level of the competition is extremely high, including Volvo Ocean Race winner Franck Cammas and the most recent Little America’s Cup winner, Fred Eaton from Canada. The Swiss team’s goal is simple: to beat the nine other teams.

Hydros is among the favorites and the boats appear to be fulfilling their potential. In training the two catamarans were foiling at speeds of 26 knots (48 km/h) in just 8 knots of wind, or more than three times the wind speed. They also reached a top speed of 34 knots (63 km/h). Note that the America’s Cup AC72 class yachts foil at twice the speed of the wind.

“Above all, as project manager, I want to show the work achieved by Hydros,” said Jérémie Lagarrigue, project leader and sailor. “Winning the Little America’s Cup would be an amazing reward for the team’s hard work.”

Jérémie Lagarrigue, Billy Besson, Mischa Heemskerk and Bastiaan Tentij, the four crew members, were the first competitors to settle down in Falmouth at the beginning of August. They have been able to train at the Little America’s Cup venue with both boats and make the final adjustments.

“We will only be able to compare our opponents’ boats on the day of the race,” said Billy Besson, skipper of one of the Hydros catamarans.

“We’re confident because both of our teams have had time to train in ideal conditions,” added Mischa Heemskerk, skipper of the second cat’. “We’ve been able to compare the performances in order to make improvements.”

Sponsored by Lombard Odier & Cie, drawn by the Design Team of Hydros in co-operation with designers Hervé Devaux Structures, Van Peteghem Lauriot Prévost and the Ecole Polytechnique Fédérale de Lausanne, this revolutionary catamaran, built in the Décision SA boatyard on the shores of Lake Geneva, is the first constructed in TPT - Thin Ply Technology.

“We’ve worked on all the aspects of the boat and the race with a very efficient team and today we’re capable of flying at impressive speeds,” said Bastiaan Tenitj, crew member of Hydros. “It was built with the lightest materials using the most modern technologies. It’s undoubtedly the most impressive boat I have ever sailed.” Eleven teams, representing seven nations will meet in Falmouth Bay from September 22 to September 28.

Source: Hydros

August 20 2013

Hydros team breaks Blue Ribbon record with l’Hydroptère.ch

Yesterday afternoon, Hydros broke the Blue Ribbon Lake Geneva record, part of the SYZ & CO Leman Sailing Speed Records, by crossing the lake (Geneva (Port Noir) - le Bouveret - Geneva) in 4 hours and 45 minutes.

Geneva, Wednesday 21 August 2013 - The flying boat l’Hydroptère.ch, piloted by Daniel Schmäh, broke yesterday the Blue Ribbon record between Port Noir and le Bouveret, with a theoretical distance of 66.5 nautical miles (123 kilometers). It thus beat the time set by Philippe Cardis on Décision 35 in 2007 by eight minutes.

"We had fantastic wind conditions yesterday," explained Daniel Schmäh, skipper of l’Hydroptère.ch. "The wind continued and reached the Haut Lac, which is quite rare and was not the case during our previous attempts. We broke a rudder on the way back, but decided to continue as we were doing well on time. Given the direction of the wind, we had to tack several times, which effectively extended the distance travelled."

This was not the first try of the team sponsored by Lombard Odier & Cie, as it had already made multiple unsuccessful attempts this year to break the record. In carrying off this feat, l’Hydroptère.ch shows that the three years of technological development were worth it. It is the third boat to win the Blue Ribbon.

Source: Hydros

August 9 2013

Solar Impulse HB-SIB Testing of the new wing spar

Pushing the limits is a tough job, but it’s a necessity when innovation is the ultimate goal. The problem is that it’s hard to know ahead of time where the limit is. Solar Impulse crossed that thin line last year, on July 5th, 2012, during the structural test of HB-SIB’s wing spar – the central part of the second solar airplane’s wings. We got too close to the edge and fell overboard: i.e. the wing spar broke. Only by persevering and learning from one’s mistakes can innovation happen. In fact, this is the attitude that made it possible to build the first solar airplane able to fly day and night with the wingspan of a Jumbo Jet, the weight of a small car and an almost limitless endurance.

The new wing spar was delivered July 19th, 2013 in Dübendorf. The engineers had no time to lose and immediately began preparations for the upcoming tests of this very large and bulky part (over 70 meters in length). The first one, a torsion test and also the most difficult one, took place on Monday August 5th. Solar Impulse engineers decided to start with the one that had caused the first spar to break in order to instantly know whether the new structure would be able to handle the load. Nothing in the configuration of the test was changed. In fact, the analysis done after last year’s incident proved that the load cases, test jigs and overall setup were indeed correct.

This series of tests will be completed by the end of August from which point the “dressing” of the wing will start. Solar panels, ribs, fabric and motor gondolas will be added to the structure bringing the solar wings slowly to life…

Source: Solar Impulse

May 15 2013

Solar Impulse HB-SIB We have a new wing spar!

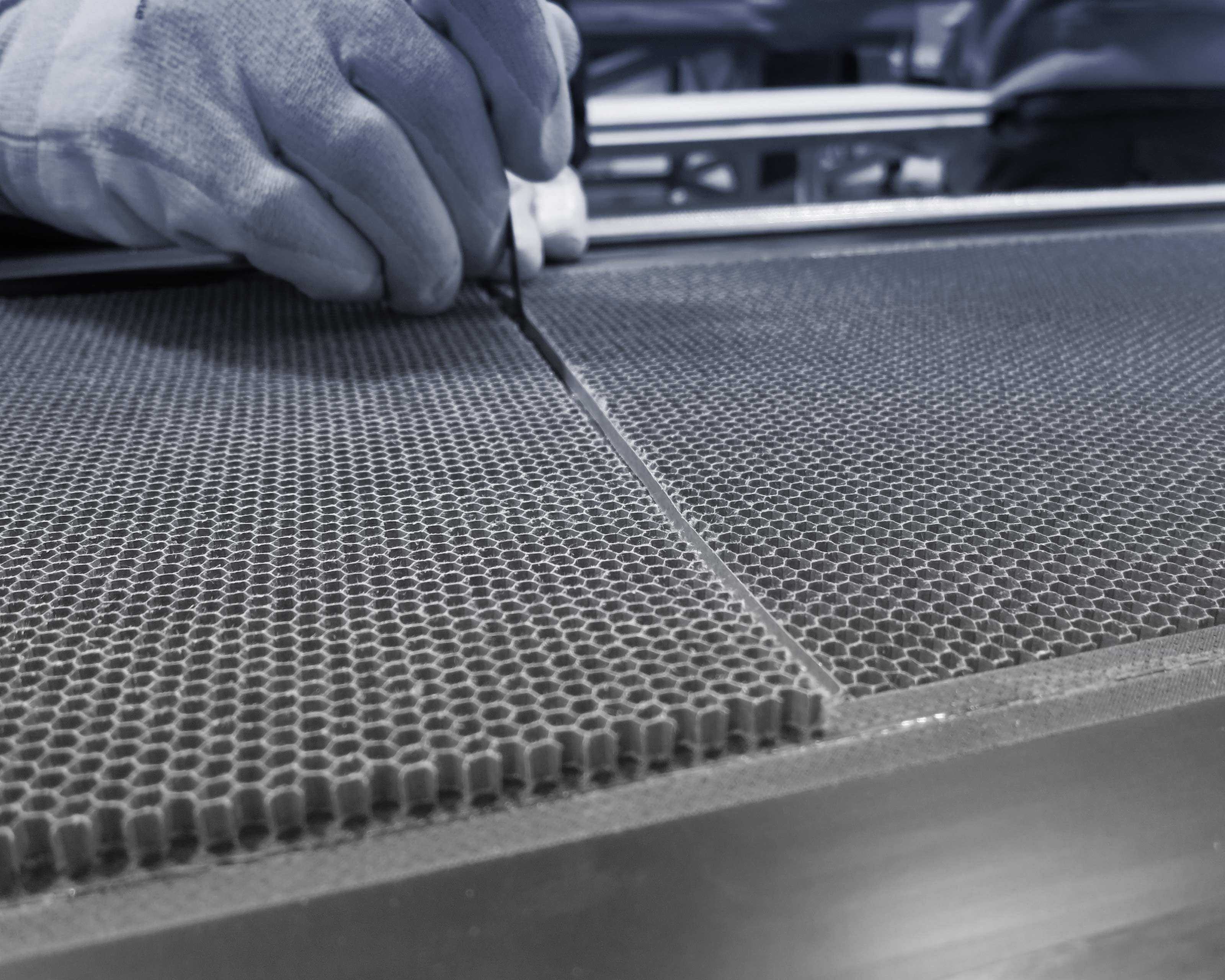

Our Solar Impulse engineers gave some incredibly good news last week when they announced that Decision, our key supplier of large carbon parts, completed the second airplane’s new wing spar.

In July 2012, during the final structural test of the wing spar, the central part succumbed to the load and broke. This was a vivid reminder that pushing the limits is no easy task and that sometimes, when you’re right on that thin border, you may fall overboard. However, what might have been dramatic in July last year has become an advantage today; the construction delay of HB-SIB brought many new and exciting opportunities such as this year’s Across America mission.

The wing spar is pretty much the solar airplane’s backbone and most important part. It’s the central structure of the wings and, in Solar Impulse’s second generation airplane, it is much larger for a plane meant to fly faster. Consequently, the wings will be subject to more loads by a factor of two. During last year’s failure only the central part of the spar broke and, after thorough testing, the two outer sections of the spar were spared. Nevertheless, the entire spar was rebuilt for consistency reasons, a process that took 10 months, as the design and the production process have since improved. The leftover outboard sections will be kept as a backup.

The wing spar looks like a long rectangular box. It’s fully made out of carbon and it’s glued – or bonded, as the engineers say - together via a very special chemical process, including 20 curing cycles, in a gigantic oven. It takes 64 minutes to bond the parts together and 88 minutes total for the final bracing and cleaning. These time limits must be strictly respected to avoid an uneven process, which can be fatal for the structural integrity of the entire wing spar.

Everything went according to plan thanks to positive collaboration between Decision and our engineers, both working hard to achieve the best and most precise results.

Source: Solar Impulse