March 8 2021

Decision SA announce new direct mould tooling technology for aerospace

Decision SA, part of the leading European composites consortium, Carboman Group, and a specialist in the development, prototyping and production of large composite structures, is proud to announce a new direct mould tooling technology for aerospace.

Decision's latest tooling solution provides OEMs and manufacturers with short lead times for highly stable direct moulds for series production both in and outside of the autoclave at temperatures of up to 180˚C.

Decision and Carboman recently delivered the first customer moulds using the new technology, providing a tooling glass prepreg, stainless-steel backed direct female mould tool created for the series production of a Class 3 fairing to a leading European aerospace OEM. Decision has immediate availability and capacity for similar tooling projects with lead times currently as short as six to eight weeks.

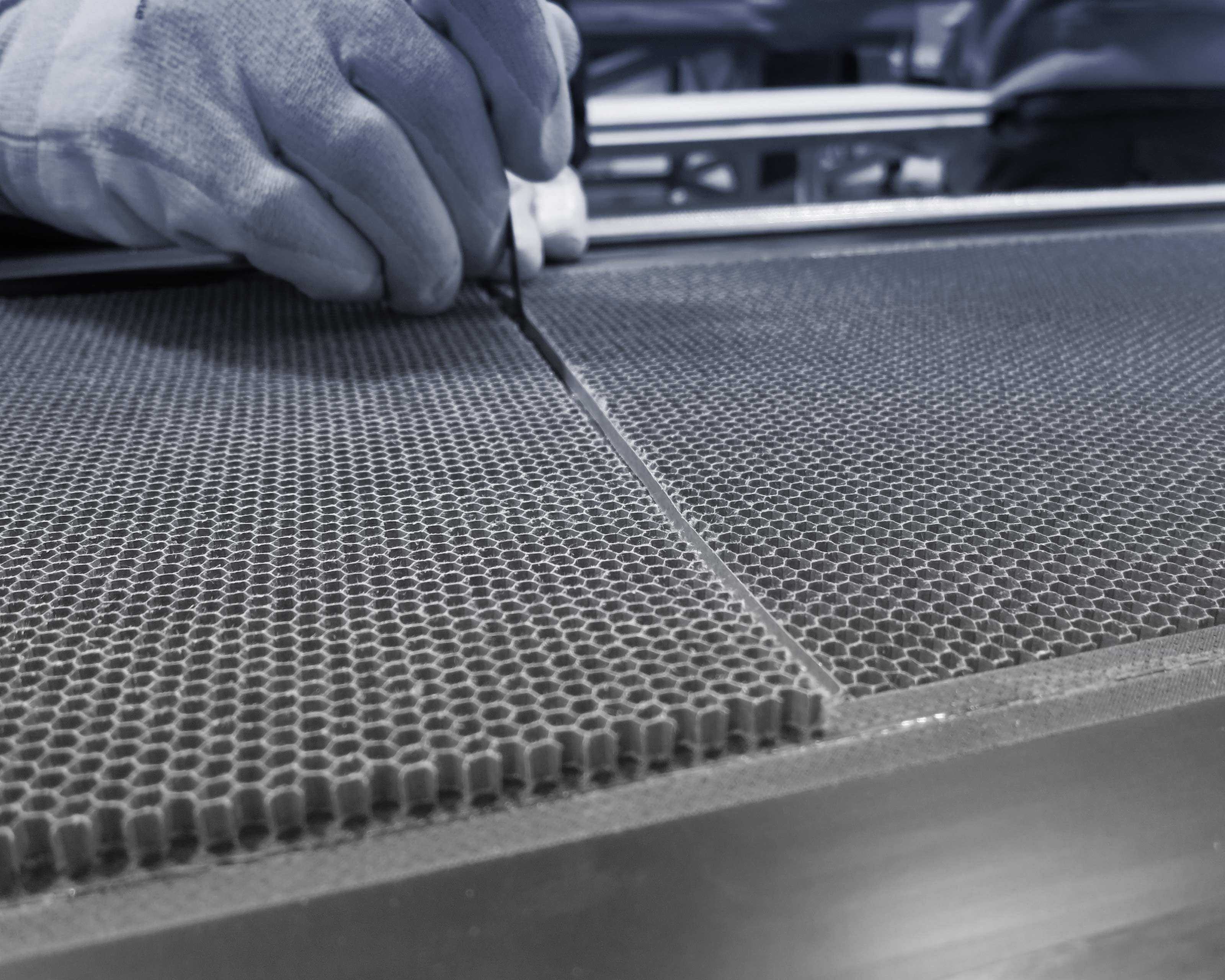

With no traditional plug or mould pattern required, Decision's direct mould process starts with the group's engineers selecting a material combination for the tool surface and support structure that will provide the optimum match between the coefficient of thermal expansion (CTE) of the mould and the composite part to be processed. The CNC machined composite face sheet is supported by a stressrelieved metallic or composite backing structure before final post curing and machining is completed. The principal benefit of this novel approach, aside from removing the need for costly and timeconsuming plug production, is the production accuracy delivered by the closely matched CTE of the mould tool and the finished composite part.

The autoclaved composite tool surface is not only extremely dimensionally stable up to processing temperatures of 180˚C, but it can also be configured with additional metallic inserts or fixtures if required.

Produced in an EN 9100:2018 controlled production environment, and with CMM checks before and after machining, the new direct composite tools have dimensional tolerances of +/-0.2mm. The available tooling dimensional envelope is currently defined by Decision’s 2200mm x 6000mm autoclave.

“With our new direct tooling technology, we are able to combine the highest technical standards in dimensional accuracy and thermal stability with extremely short lead times. Decision and Carboman Groups’ combined mission has always been to develop the construction methods for tomorrow’s composite structures, and we believe that this tooling solution will allow our customers to accelerate the implementation of the next generation of high-performance carbon fibre aerostructures and components” Grégoire Metz, Managing Director, Decision SA.

February 2 2021

Decision SA is proud to be part of the refit of the boat "Rhône".

Decision SA proudly collaborates with CGN for the refit of its fleet of historical ships with the construction of the topdeck roof of the boat "Rhône", which is produced with fire resistant composite materials.

May 15 2020

Decision SA on the cover of Swissmem Network magazine

Thanks to Swissmem for the interest shown in our company and its activity through this article.

Our membership of Swissmen reflects our desire to strengthen our local anchoring and to offer solutions in #performanceplastics manufacturing to Swiss manufacturers!

For more information, read the press article.

February 11 2020

Decision SA is pleased to participate of the largest composites show, JEC World 2020 in Paris, France.

Decision SA will be exhibiting at booth M86 in hall 6, between 3-5 March 2020 at the JEC World in Paris.

As the composites industry's most significant annual event, JEC World is hosting the major players in a spirit of business and networking. With 1,400 expected exhibitors and more than 45,000 expected professional visits from 112 countries, the event promotes the composites sector's biggest innovative projects and has become a global festival, and the undisputed reference for the composites industry.

Decision SA invites you to visit its booth to see our facilities, technological innovations and latest projects done in composite materials.

January 9 2020

Decision SA active on the urban air mobility

Decision SA continues to be very active in the fabrication of composite airframe structures of electric vertical take-off and landing (eVTOL) flying machines intended for the mobility of the future.

Due to the proprietary nature of our projects Decision SA is unable to publish any information, including photographs, of these current projects.

However, do not hesitate to contact us about your future projects.

August 26 2019

An autoclave for Decision SA

Arrival of our new autoclave at Decision SA – Carboman Group.

With the following main characteristics:

2,2m x 6m internal dimensions

Temperature 250°C

Pressure 10 bars

It is fully operational and ready to welcome your future achievements.

Consult us for your projects.