SolarImpulse HB-SIB - 2014

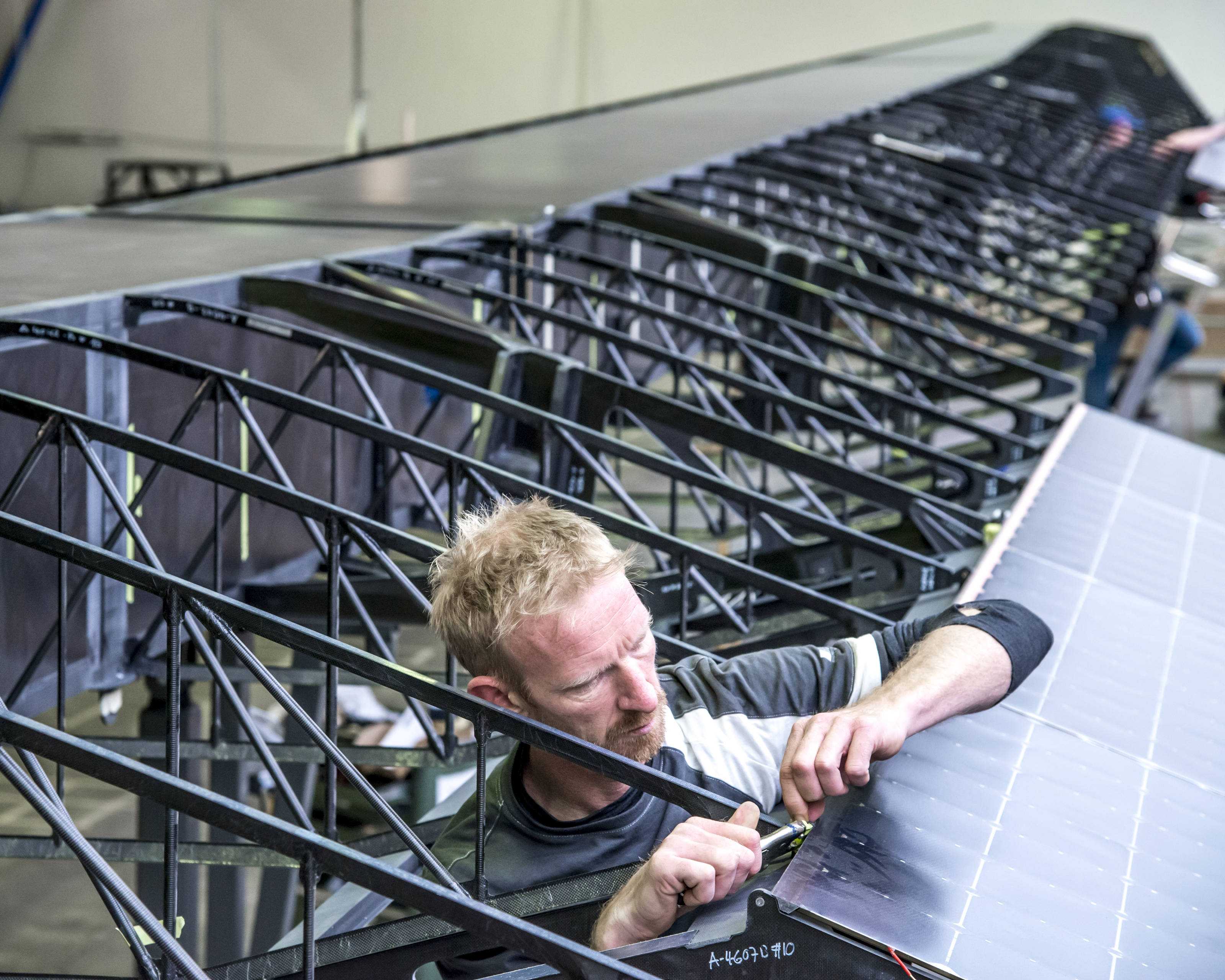

Production of the main structures, such as: wing spar, fuselage, cockpit, tail structure and more

The chances of succeeding at the first attempt to build a solar airplane capable of flying around the world were judged to be slim, so a more rudimentary prototype, HB-SIA, was first constructed.

Lessons learned from this prototype are incorporated in the second airplane, to be registered as HB-SIB, construction of which was started in 2011. Its more spacious cockpit will enable the pilot to fully recline during flights lasting from 4 to 6 days; it will have an increased payload; its electrical circuitry will be isolated to enable flights in rain; and system redundancy will improve reliability.

Whereas the prototype uses existing technologies, Solar Impulse HB-SIB requires the development of new materials and new construction methods. Solvay has invented electrolytes that allow the energy density of the batteries to be increased; Bayer MaterialScience is allowing the project to make use of its nanotechnologies; and Décision is using carbon fibers that are lighter in weight than any previously seen

The first wing spar section was delivered to Dübendorf in March 2012. However, during the final test of this central part, the structure of the wing spar succumbed to the load and broke. The initial shock soon turned out to be an opportunity: the flight around the world had to be postponed which opened the door for going to the United States and completing the epic journey across America.

After the official presentation of Solar Impulse 2 to the public on April 9th, flight testing is planned for spring 2014, and the round-the-world flight for between April and July 2015.

Source: Solar Impulse

| Year: | 2011 à 2014 |

| Wingspan: | 72m |

| Weight: | 2300kg |